17 Types of Home Windows - Costs and Pictures - by Brennan

Are you trying to decide on the right window type for your home? Maybe you’re in the process of building a house or looking to remodel your existing one. Either way, you'll benefit by learning about the different types of window styles and their price ranges.

Here is a list of the most common window types, along with pictures and price ranges.

1. Single-Hung Windows

Single-hung windows are the most popular window our clients ask for and they open vertically from the bottom window sash. The upper sash remains in place and is covered by the lower section. They’re simple, easy to use, and fit into most home designs.

Single-Hung Window Price Range*

Window details: vinyl, white, 30" x 60", double strength glass, Low-E 366 + argon Cardinal glass or a close substitute.

Prices range from $285 - $645, depending on window quality, frame depth, frame profile, manufacturer, and overall performance.

2. Double-Hung Windows

The key difference between single and double-hung windows is that both panels can move up and down on the double-hung. If you opt for a til sash, it is easy to clean the windows from the inside. Double-hung windows also offer excellent ventilation and provide you with greater control over airflow. Therefore, they’re great for rooms that tend to get stuffy or areas that are highly populated.

Double-Hung Window Price Range*

Window details: vinyl, white, 30" x 60", double strength glass, low-e 366 + argon Cardinal glass or a close substitute.

Prices range from $325 - $750, depending on window quality, frame depth, frame profile, manufacturer, and overall performance.

3. Awning Windows

An awning window opens outwards from the bottom of the panel. They're commonly wider than they are tall and often are paired with large picture windows to improve ventilation.

Awning Window Price Range*

Window details: vinyl, white, 48" x 30", double strength glass, Low-E 366 + argon Cardinal glass or a close substitute.

Prices range from $380 - $1,020 depending on window quality, frame depth, frame profile, manufacturer, and overall performance.

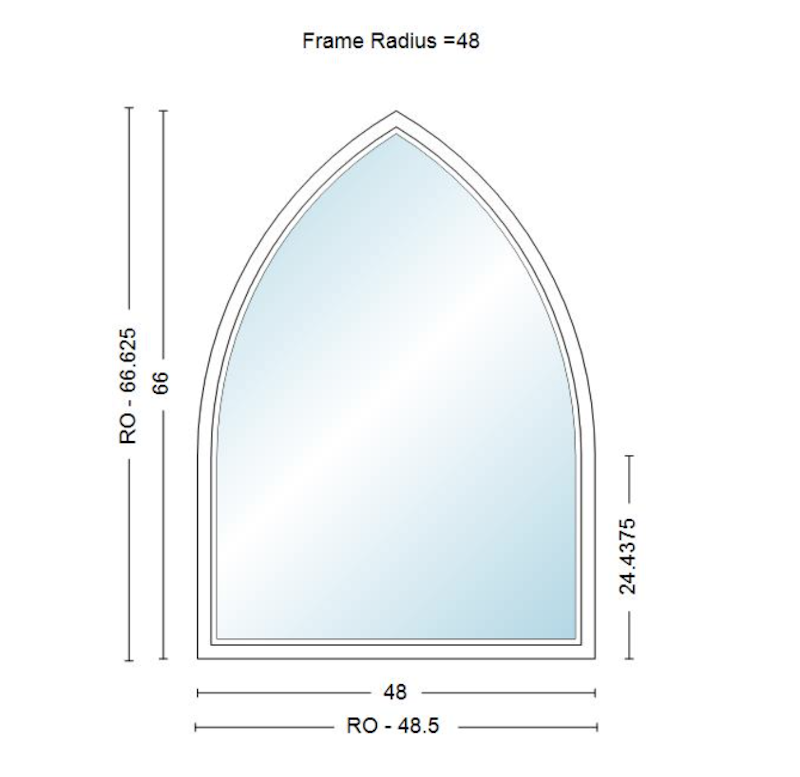

4. Arched Windows

Arched windows make sense for home styles that have steeply pitched roofs with steep cross gables, are two stories, and are designed as Gothic Revivals or Exotic Revivals. Queen Anne-style homes are often thought to have arched windows, but most arches associated with Queen Anne's are decorative gables.

Arched Window Price Range*

Window details: wood-clad, white exterior, pine interior, 48" x 66", double strength glass, Low-E 366 + argon Cardinal glass or a close substitute.

Prices start at $2,760 depending on window quality, frame depth, frame profile, manufacturer, and overall performance.

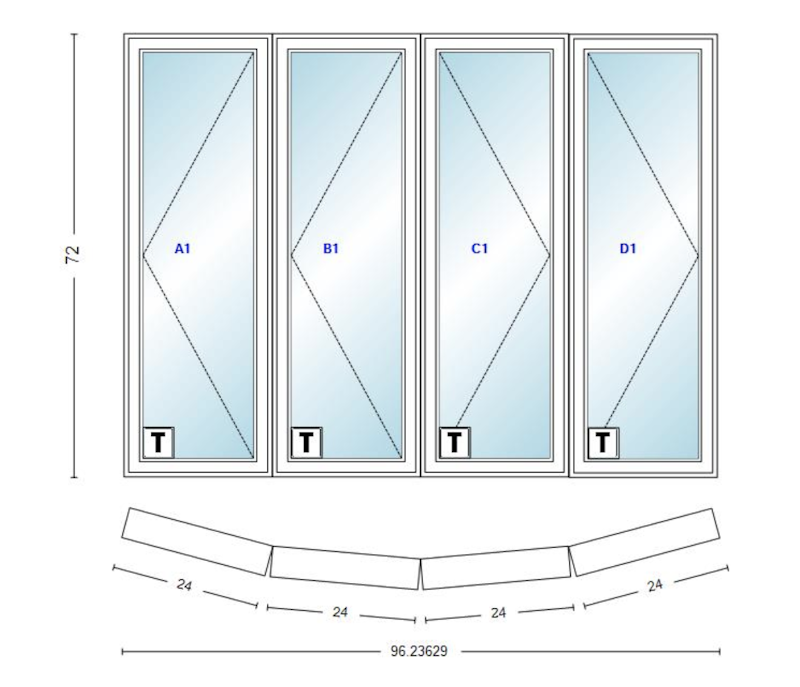

5. Bow Windows

Bow windows are available in a push-out style, where they extend beyond the footprint of the room as well as inside the wall framing, so it encroaches into the square footage. Bow window configurations can be comprised of different window types, such as single-hung windows, casement, or picture windows.

Bow windows are typically considered when building a new home rather than replacing a traditional window with a bow.

Bow Window Price Range*

Window details: wood-clad, white, 96" x 72", 4 units, push-out casement bow, double-strength glass, low-e 366 + argon Cardinal glass or a close substitute.

Prices start at $7,500, depending on window quality, frame depth, frame profile, manufacturer, and overall performance.

6. Bay Windows

Bay Windows protrude from the wall while also creating an additional shelf. You can use this space for extra storage or a place to relax while you soak in the sunlight or watch the rain. Bay windows can be added to any home but will require additional roof framing and support framing under the window unit. If you have an existing bay window, make sure your support framing is in good shape before installing a new window on a compromised foundation.

Bay Window Price Range*

Window details: vinyl, white, 20" x 63", 54" x 64", 20" x 63" double strength glass, low-e 366 + argon Cardinal glass or a close substitute.

Prices range from $1,315 - $2,075, depending on window quality, frame depth, frame profile, manufacturer, and overall performance.

7. Casement Windows

Casement windows provide more natural light than other operable windows because they are built with one unobstructed piece of glass. Casements often have a bulb seal and weatherstripping around the perimeter which provides a weather-tight seal when closed. The biggest downfall to casement windows is their limited size range. The weight of the glass sits on one piece of hardware which has weight limitations, so most casement windows can't be built larger than 36" wide x 60" tall.

Casement Window Price Range*

Window details: vinyl, white, 30" x 60", double strength glass, low-e 366 + argon Cardinal glass or a close substitute.

Prices range from $440 - $950, depending on window quality, frame depth, frame profile, manufacturer, and overall performance.

8. Garden Windows

As the name suggests, this replacement window type is ideal for plants and flowers. It’s a smaller version of the bay window style and acts as a greenhouse for your indoor garden.

This style brings in more light and fresh air as there are often more panels than other replacement window types. These are great for kitchen areas, especially if you have a miniature herb garden.

9. Glass Block Windows

Glass block windows were common in the 80's and 90's to create privacy in bathrooms. Today, glass blocks have waned in popularity as obscure glass is available in traditional window frames. In years past, glass block was heavy because it was indeed made of glass, but today's glass block windows are often made of lighter acrylic material.

10. Picture or Fixed Windows

These windows don't open and often complement operating windows nearby. The positive to picture windows is that they typically cost less than operating windows and can be built in a wide range of shapes and sizes. Don't think you can have all picture windows because building codes require an operating window that meets egress in every bedroom.

Picture Window Price Range*

Window details: vinyl, white, 30" x 60", double strength glass, low-e 366 + argon Cardinal glass or a close substitute.

Prices range from $285 - $595, depending on window quality, frame depth, frame profile, manufacturer, and overall performance.

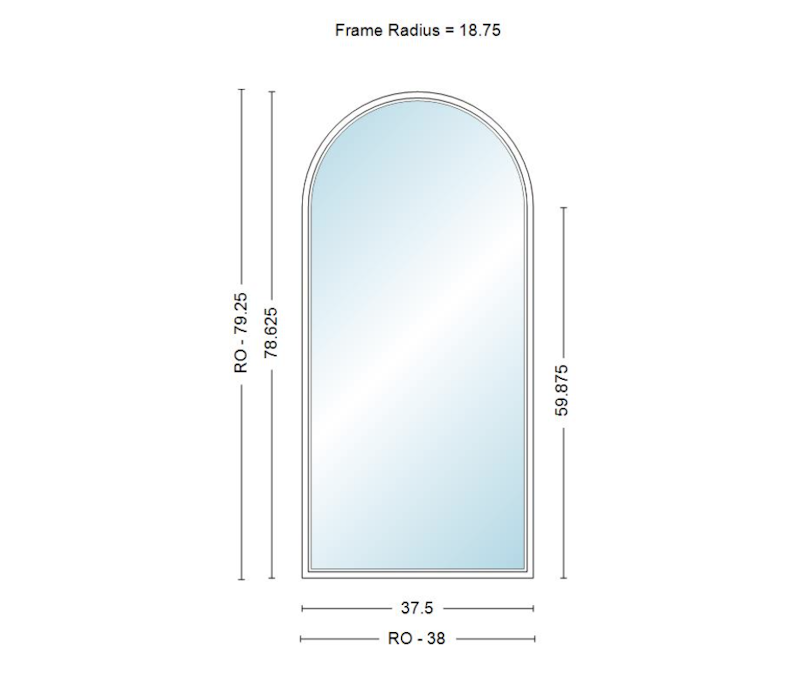

11. Round or Circle Top Windows

Roundtop windows have fallen out of favor within new construction unless you're building a Spanish-style estate. However, during the 90's and 2000s, Texas builders used circle top windows to add a bit of flair to traditional single-story brick homes. These windows are often used as transoms above operating windows. Sometimes, the round top windows are operators where the top, rounded sash is fixed and the bottom rectangular sash operates.

Round Top Window Price Range*

Window details: wood-clad, white exterior, pine interior, 38" x 79.25"", double strength glass, Low-E 366 + argon Cardinal glass or a close substitute.

Prices start at $2,532 depending on window quality, frame depth, frame profile, manufacturer, and overall performance.

12. Storm Windows

Storm windows were invented and installed before the advancement of window technology. Today, storm windows are very rare because you can improve the efficiency of your windows with new and improved glass and frame technology. Not to mention, storm windows are a maintenance nightmare. Once installed, water, dirt, and grime get behind the storm window and fog up the view from inside your home. Just say no to storm windows.

13. Skylight Windows

Some homes have limited options when it comes to providing natural light. One solution is to install a skylight. You can choose to install a single panel or make it a functional window that opens and closes. Skylight windows are often used to bring light onto a patio cover. Velux skylights is the only vendor we recommend.

14. Sliding or Gliding Windows

A sliding window can consist of two or three sections. Some manufacturers build sliders so only one section slides while others allow two operable sections. We call a sliding with one operable sash a one-light slider and a two-light slider for sliding windows with two operable sections.

Sliding/Gliding Window Price Range*

Window details: vinyl, white, 60" x 30", double strength glass, low-e 366 + argon Cardinal glass or a close substitute.

Prices range from $285 - $1,065, depending on window quality, frame depth, frame profile, manufacturer, operating configuration, and overall performance.

15. Transom Windows

Transom windows above interior or exterior doors are a decorative feature added to increase the height of a room or let more light in. Transom windows can also be affixed to the top of operable windows so create a grand window wall. These windows come in all shapes and sizes including eyebrows, half-circles, rakes, and more.

Transom Window Price Range*

Window details: vinyl, white, rectangular window, 36" x 28", tempered glass, low-e 366 + argon Cardinal glass or a close substitute.

Prices range from $390 - $735, depending on window quality, frame depth, frame profile, manufacturer, and overall performance.

16. Entry Door Sidelite Windows

A sidelite window is a vertical piece of glass placed on the sides of an entry door. It allows more natural light to enter your home and can further enhance the exterior appearance of your door. Glass sidelites are available in different styles including full-view, quarter-view, half-vier, and more. Not all sidelites are mulled to the entry door. In some cases, sidelites are actual windows (from the window manufacturer) that have been framed beside the entry door.

Sidelite Window Price Range*

Window details: the sidelites are the same height as the door frame, so they're typically 80", 82", or 96" tall and the width starts at 16" but can be narrower or thicker depending on your design. The glass for sidelites will always need to be tempered, which increases the price of the windows.

Prices start at $550 for slim vinyl, picture window sidelites and can go up to $3,000+ for decorative hardwood sidelights with art glass.

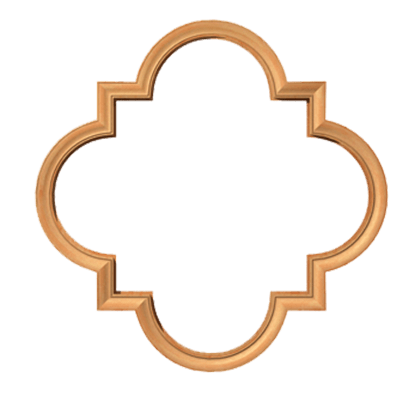

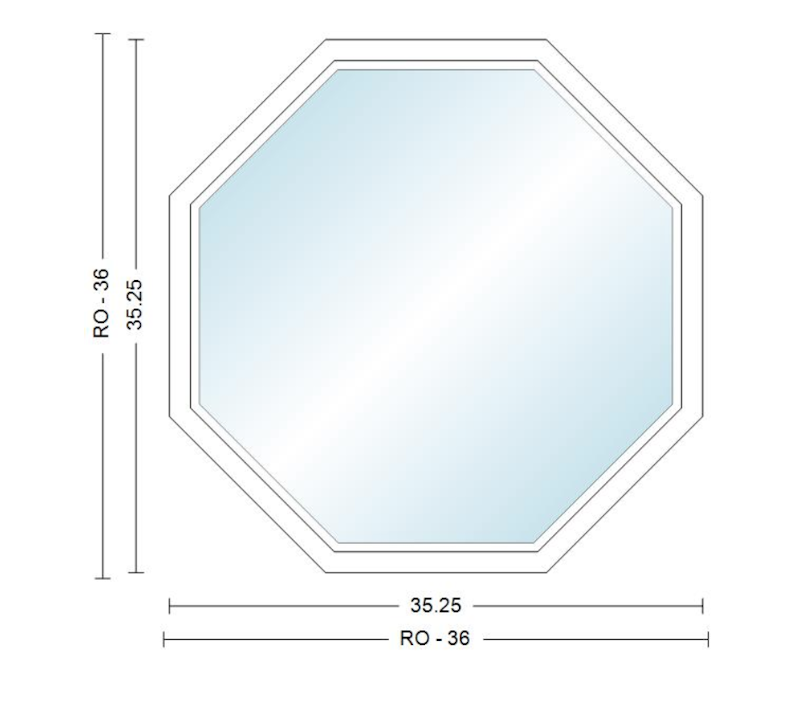

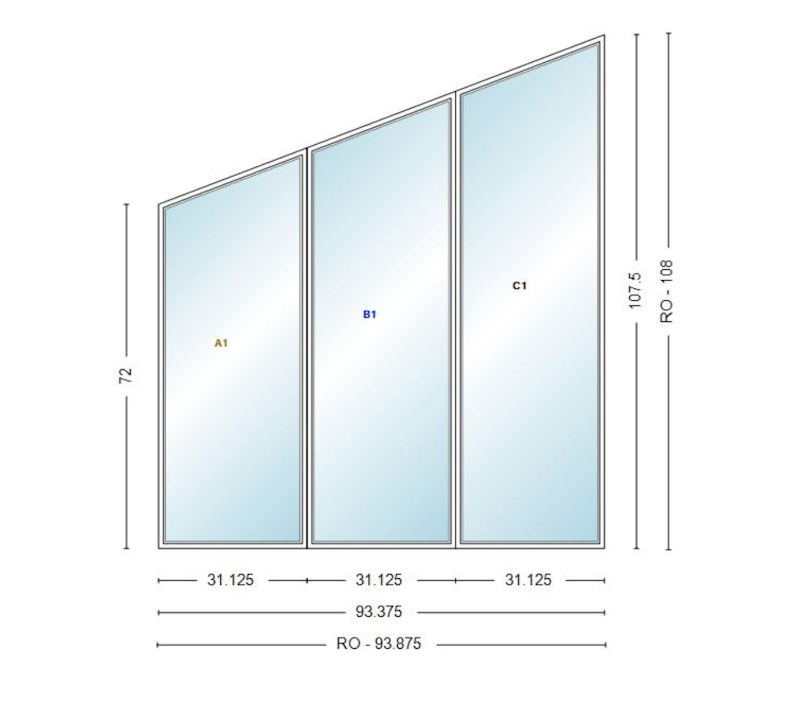

17. Specialty Shape Windows

Often used to highlight a view, or a focal point of your home, specialty shape windows can be fixed or operating windows. Choose from hundreds of shapes to craft your perfect opening.

Specialty Shape Window Price Range*

By their nature, specialty shape windows are difficult to price because of the varying sizes, shapes, and configurations. In the images below, I've included the prices of two specialty shape window configurations.

Window details: wood-clad, white exterior, pine interior, Low-E 366 + argon Cardinal glass, non-operable.

*Window Pricing Range Notes

- No price includes tax or installation

- Prices accurate as of published date 10/21/2021

- Prices are subject to change

At Brennan, we provide and install world-class windows and doors for customers across North Texas. If you'd like to explore your window or door options, you can browse our windows and doors, or request a free estimate.

News, Product Reviews, and Insights

Oops!

We don't currently serve your area but do want to help you plan your project. Try our Build & Price tool to get an idea of window & door costs within DFW. Your area may be higher or lower but at least you'll have some idea of the price.

Thanks for stopping by.